Performance

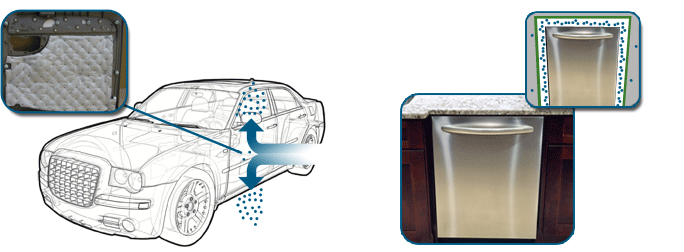

Through its proprietary process, AIM manufactures high-performance, low-cost acoustical and thermal absorption insulation. This energy saving insulation is made from polypropylene, and is used throughout the world. AIM’s insulation is fully recyclable and safe to use. The “no itch,” odor-free insulation improves sound and energy where you live, work, and in your car.

Through its proprietary process, AIM manufactures high-performance, low-cost acoustical and thermal absorption insulation. This energy saving insulation is made from polypropylene, and is used throughout the world. AIM’s insulation is fully recyclable and safe to use. The “no itch,” odor-free insulation improves sound and energy where you live, work, and in your car.

Customization is a core strength of AIM products. The AIM team is able to design applications based on customer specifications. The acoustical and thermal fibers are melt blown through an extrusion process that produces thin, fine, fibers that absorb sound and keep energy from escaping.

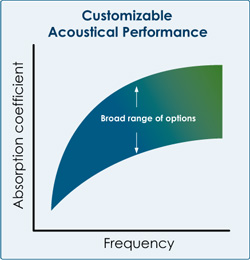

Acoustical Performance

AIM sound-absorber products are typically designed to attenuate air-borne noise energy (i.e. energy that is being transferred through the air). When the sound energy penetrates the AIM insulation, it becomes absorbed within the fibers and facings through friction, greatly diminishing the remaining sound energy. AIM products are designed in a range of offerings/thicknesses to provide high performance at a wide range of frequencies.

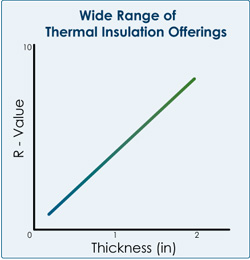

Thermal Performance

AIM material has a very low density. It is very porous and encompasses a significant amount of air. Air itself is a very poor conductor of thermal energy. Our insulation’s fine fibers form pockets of air, minimizing the opportunity for convection. The AIM products exhibit a wide range of thermal properties – from R=1 to R=7 and grater.